Kochi Kigata Kogyo Co.,Ltd.'s core strengths are the mold fabrication technologies, experience, and knowhow which we have cultivated over the company's long history. Our engineers are expert craftspeople who possess a refined set of specialist skills and are extremely skilled at precision mold fabrication with a variety of materials. These expert craftspeople consistently achieve high quality, and their high level of technical ability enables them to provide proposals to realize not only the desired forms, but also for optimization of cast products to achieve the required strengths and shapes.

We can utilize 3D printing technologies based on laser molding to create prototype cast products without the need for molds. This reduces the time required to create prototype molds, and allows for quicker provision of prototypes, both of which contribute to reduction of lead times for development of customer equipment which utilizes cast components. This also makes it possible to carry out mold fabrication with consideration for materials, machining, assembly, and other processes, contributing to an overall reduction of costs.

We can reduce the time required from processing of materials, assembly, and deburring to shipping and also decrease defect ratios. This allows us to provide proposals for comprehensive cost reduce for all design, mold fabrication, casting, processing, and assembly processes.

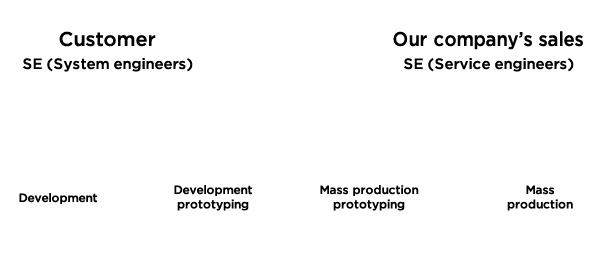

Kochi Kigata Kogyo Co.,Ltd. doesn't just "manufacture" products. We participate in the development and fabrication of cast components from the equipment design stage, and can also carry out component design and prototyping with consideration for production, machining, and assembly. The idea that "casting molds are ordered after machine design is completed" is a widely held concept, however having our company's service engineers, who are intimately familiar with processing ease and other aspects of casting, involved from the design stage allows for the incorporation of production site knowhow into the design. The aim of this is to improve overall production efficiency through the utilization of these higher quality products. Comprehensive cost reductions and shorter delivery times can then be achieved by further employing digital central management of design, development, manufacturing, mass production, and all processes.

Kochi Kigata Kogyo Co.,Ltd. utilizes the latest, cutting-edge 3 dimensional measurement instruments, surface roughness testers, carbon analyzers, hardness testers, X-ray fluorescence spectrometers, and microscopes to carefully and thoroughly inspect every individual workpiece. Our in-house Quality Assurance Department carries out inspections of not only products from our own company factory, but also of all procured materials. We prioritize providing high quality products with no defects or mistakes above all else.