| Business name | Kochi Kigata Kogyo Co.,Ltd. |

|---|---|

| Established | 3/10/1965 |

| Corporate officers | Chairman - Masanori Kita President - Masayuki Kita Vice President - Yasuko Kita Director - Hiroshi Yamanaka Director - Hiroaki Ido Auditor - Risa Kita |

| No. of Employees | 35(9/2020) |

| Capital | 34 million yen |

| Site area | Head Office / Lot: 14,261.68 m2 Office/Factory: 7,604.08 m2 |

| Address | ■ Head Office & Main Factory 1244-1 Kagamicho-Shimobun, Konan-shi, Kochi, 781-5452 Tel.+81-887-50-3988 Fax.+81-887-55-3906 ■ Dalian Office 7 Xin Feng Jie, Ganjingzi Qu, Dalian Shi, Liaoning Sheng, China, 116081 Tel.+86-411-8228-2881 |

| Business Description | Various mold fabrication and procurement of formed and fabricated materials businesses |

| Products | Metal molds Machinery wooden molds Shell molds Styrofoam models Master models Cast steel products, cast iron products, stainless steel products (SC, SCW, FCD, AC, TI) Semi-lost wax and composite-lost wax and lost wax casting products Laser molding products D.Q.C (Digital Quick Casting) products |

| Banks of Account | Shikoku Bank Shoko Chukin Bank Awa Bank Tokushima Taisho Bank Hata Shinkin Bank MUFG Bank |

| Business name | KTK Ltd. |

|---|---|

| Established | 8/1990 |

| Address | 1124-1 Kagamicho-Kamibun, Konan-shi, Kochi, 781-5451 Tel.+81-887-55-4344 Fax.+81-887-55-4389 |

| Business Description | Machining and metal mold processing |

| Capital | 30 million yen |

Our company has established a Quality Policy based on the management philosophy "We will dedicate ourselves to high quality mold fabrication in order to satisfy customers and contribute to society". In order to achieve this:

We shall utilize PDCA as a tool to construct and continually improve the quality system, and work towards achieving a "PDCA improvement spiral" in order to improve product quality and allow for work to be carried out efficiently.

2015/3/10

President Masanori Kita

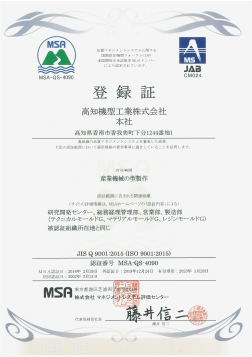

Our company has acquired Quality Management Systems certification in accordance with the ISO9001:2015 international standards for quality management, and will continue to carry out quality management going forward while also continually striving to make improvements.

The Quality Assurance Department utilizes a variety of analysis equipment and measurement instruments to carry out strict checks in order to ensure that product function and performance requirements are fulfilled.

| Name | Model | Manufacturer |

|---|---|---|

X-ray fluorescence spectrometer |

ZSX-100S |

Rigaku Corporation |

Carbon analyzer |

EF-110 |

Horiba Ltd. |

Brinell hardness tester |

FBH-01 |

Fuji Testing Machine Corp. |

Rockwell hardness tester |

3NR |

Nakai Precision Machinery Mfg. Co., Ltd. |

| Metal grinder / metallurgical microscope | 4XC |

― |

3 dimensional measurement instrument |

XM-C1000 |

Keyence Corporation |

3 dimensional measurement instrument |

FARO EDGE |

FARO Technologies, Inc. |

| Geomagic | ― | 3D Systems |

| Poly Works | ― | Poly Works Japan |

Surface roughness tester |

SJ-210 |

Mitutoyo Corporation |